This section will cover the final steps of installing the track system. This includes fitting the safety components along with some finishing touches to the track edges.

10.3.1 File Track Edge

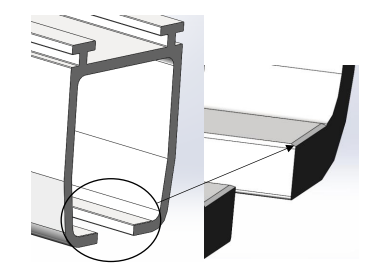

When installing any track into a 110mm bracket, transition gate or turntable, to ensure the ceiling lift transitions smoothly between each track, use a flat file to chamfer the track (in the below location) ensure there isn’t any square edge present.

10.3.2 Safety Components

To close of the track system, a safety bolt, end stop and end cap is required at either end of the system. If the ceiling lift is being installed at the same time, then the charging dock will replace an end stop at one end, (not applicable for constant charge systems).

Standard Track & Insert Constant Charge Systems

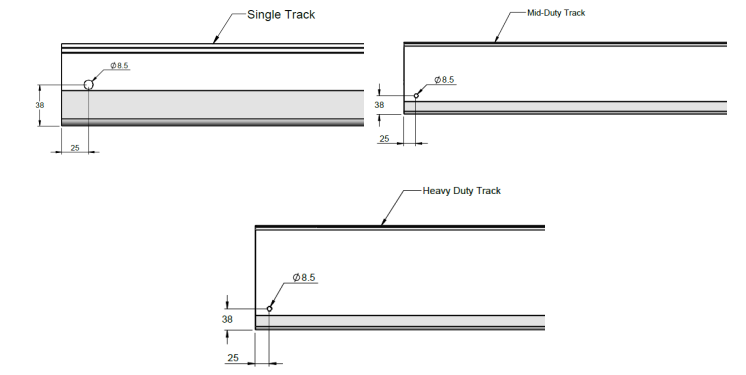

To fit the safety bolt, an 8.5mm hole must be drilled through the track 25mm from the end. For standard systems, see the diagrams below on hole location.

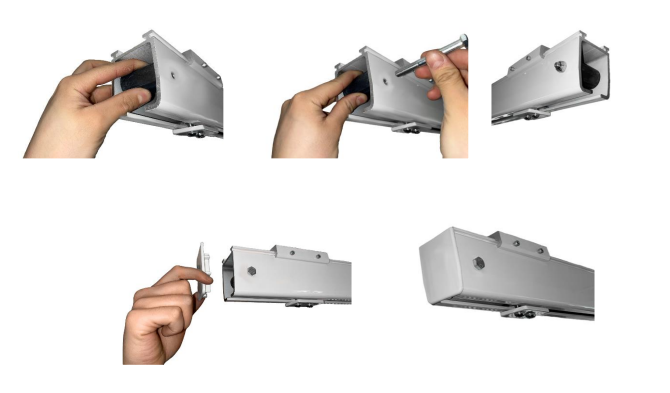

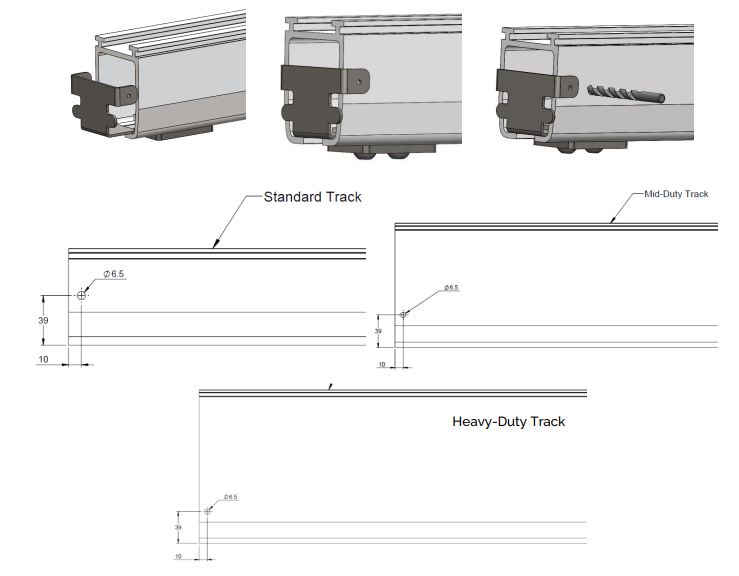

After drilling the safety bolt hole, slide the end stop into the track with the bumper facing inward. The end stop can be secured by clamping the end stop together within the track. This is done using a 5mm Allen Key on the two bolts. The end stop should be secured close to the end of the track system, but leaving enough space for the safety bolt behind.

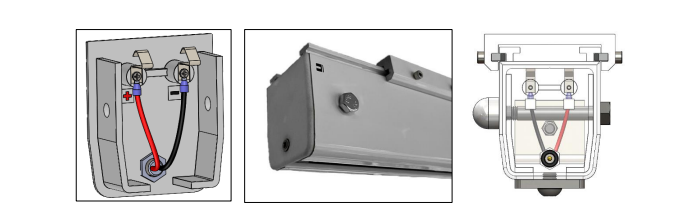

Once the end stop is secured, the safety bolt and end cap can be fitted. Place the rubber bumper inside the track, aligning it with the drilled hole and place the given bolt through the track and bumper and secure at the other end with the nut. This is done using two 13mm combination spanners. The end cap is push fitted into the track profile as shown below.

Constant Charge Track (Strip Version) Systems

To fit the safety bolt, an 8.5mm hole must be drilled through the track, a drill template is available to align and drill a pilot hole (3mm). If this is not at hand, use the diagrams below to correctly position the hole.

For constant charge track systems, a variant end cap is used, fitted with contact terminals that contact the charge strips on the inside of the track, the end cap is push-fitted into the track profile as normal but is secured in place with the safety bolt as shown, the safety bolt is not fitted with a rubber bumper as it’s not required.

Note: Old-style constant charge follows the same method as the standard end cap. See above for details