If the two direct fixing walls are not suitable for wall-to-wall fixing method 1, (i.e. Stud Walls), the opposing walls can be used as fixing points, (assuming they are solid).

The wall-to-wall fixing method is used when the ceiling is not suitable for fixing the track system, where the track system cannot be fixed to the ceiling at any point.

The wall-to-wall fixing method 2 has two options, where you can use a simple T-Bracket to span off parallel tracks or use a specialized steel supporting box section to span parallel across the room which the track can mount onto using specialized brackets.

The section below will give full instructions on the recommended method of installation for a ceiling track system into a wall fixing when the standard wall-to-wall fixing method is not suitable.

A full assessment should have been conducted to ensure that the wall is safe for installation, but the installation engineer must always be vigilant and ensure that the track fixing locations are safe, any signs of cracking, or any other damage to the wall should be avoided. Depending on the type of wall material, the various fixing methods must be followed.

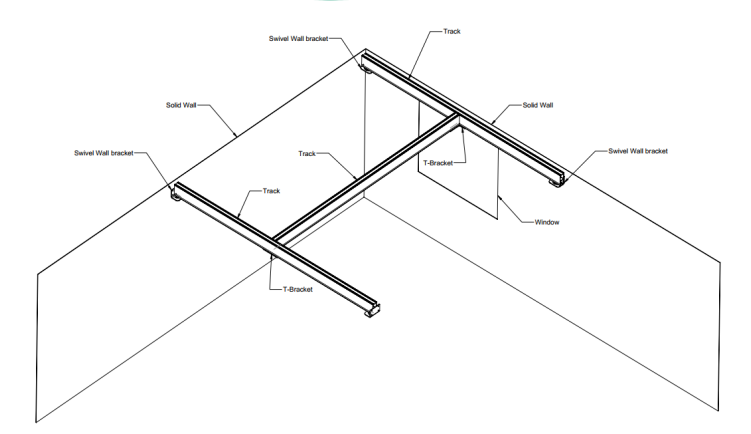

For ceiling track wall fixings, only solid walls are suitable for installation. This includes brick and block materials. To ensure the wall material is suitable, drill a small hole 0.3” (7mm) where the wall bracket is to be fitted to check the material of the wall. A wall-to-wall fixing cannot be fixed directly above a door or window as the fixing cannot be fixed to a lintel. This will not be a sufficient fixing point to bare the load of a ceiling track system.

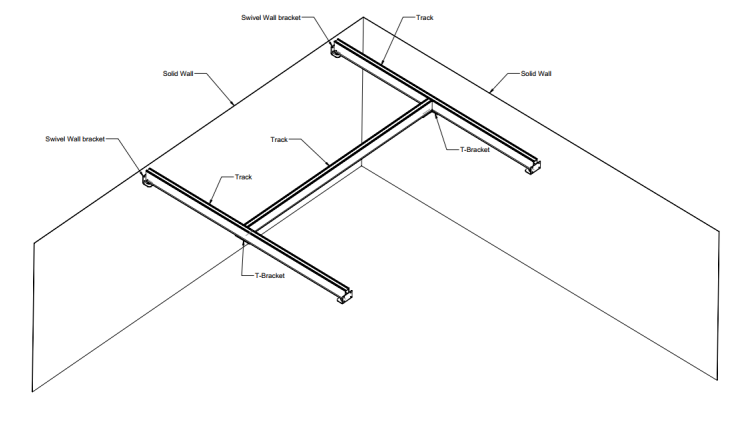

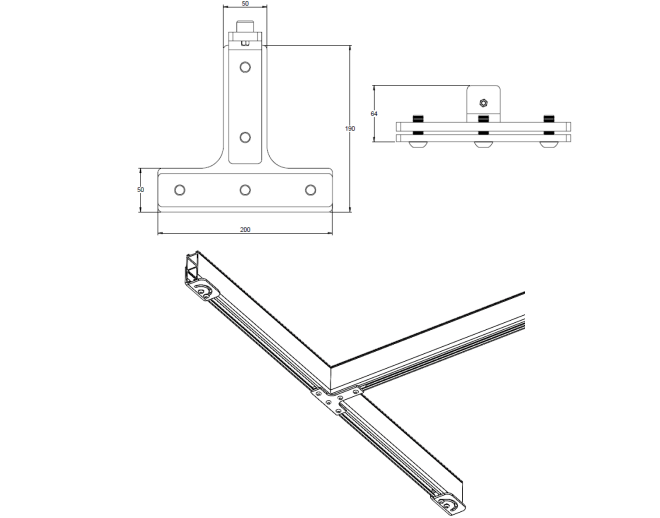

5.2.1 T-Bracket Fixing Method

The T-Bracket is used in conjunction with two parallel tracks which are installed onto the walls using the swivel brackets.

This may be onto the opposing walls as the direct wall is not suitable or onto the direct wall but a door header is in the way of direct mounting onto the wall.

The T-Bracket must be slid onto the parallel tracks and clamped using a 5mm Allen Key in its desired location. The spanning track must then be placed onto the T-Bracket and is secured in the same fashion.

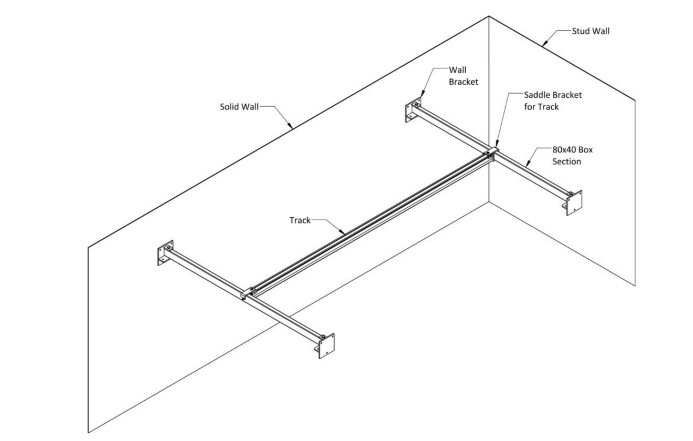

5.2.2 Aligning a Wall-to-Wall Fixing Method 2 onto the Walls using Steelworks

See the image below of a typical wall-to-wall fixing method 2 using steelworks. This method is typically used for greater spanning distances of the parallel “tracks”, as the T-Bracket will not be suitable.

When a track system is installed onto a wall fixing or a wall-to-wall fixing, it is essential to ensure that the track system is level to ensure that the fixings will align. The wall-to-wall fixing method 2 includes four wall fixings that must be aligned horizontally. Follow the guidance below:

1. Measure the distance between the two fixing walls.

2. The steel box sections must be cut to a suitable length, this will be the distance between the two walls subtracting 0.8” (20mm).

3. Determine the spanning requirements of the track system and choose a suitable track type for the installation at hand. See section 1 for maximum track spans.

4. Along the full length of the track installation, any obstacles must be avoided, this includes obstacles such as light fixings, sprinklers, etc. To accommodate this, the wall fixings’ maximum height should be 50mm below the lowest obstacle on the ceiling. This will also provide a clearance gap for the track bracket fixings above the wall bracket’s upper face.

5. Determine a suitable location for the first wall bracket fixing. Align the wall bracket as close to the ceiling as possible to provide maximum track height. Depending on the wall type, the bracket must never be fixed to the top two bricks, as this will not provide sufficient strength to support the track system, always ensure that the fixing point is secure.

6. Place the wall bracket onto the wall and mark out all the hole fixings onto the wall with a marker/pencil. See the diagram below for hole positions.

7. Using a laser, the second bracket position can be marked on the opposing wall to provide a level fixing.

8. Using the laser and a tape measure, position the third and fourth wall fixing on the wall, and mark out the fixing positions.

5.2.3 Fixing the Wall to Wall Fixing Method 2 to the Walls

To fix the wall-to-wall fixing method 2, the fixing method must be split into sections, this includes fixing the steel wall brackets, the steel box section, and the saddle brackets with the track. See the guidance below for the correct method of fixing. Ensure to first refer to section 5.2.1 for the correct alignment and marking out the positions of the wall brackets.

Steel Wall Bracket Fixing

When fixing the wall bracket to the wall, the best fixing method is to fix the threaded bar directly into the wall through the process of chemical resin. There will be three fixings to support the wall bracket, and the threaded bar must be inserted a minimum of 70mm to provide suitable strength to support the ceiling track. The wall bracket must be installed into a wall that is in good condition, ensuring that there are no cracks or weaknesses found during placement.

When using the chemical resin, always ensure to follow the manufacturer’s instructions along with the guidance of this manual.

1. Align the steel wall bracket up against the wall to ensure the pre-marked hole positions remain true.

2. As the wall is solid concrete or similar block material, drill the three marked holes to a minimum depth of 70mm, this depth provides suitable strength for the fixing to support the track. A 16mm drill bit diameter should be used.

3. Once the holes have been drilled, they must be cleaned out, a hoover, air gun or hole brush will suffice.

4. Ensure the drilled hole positions remain true.

5. M12 threaded bar should be cut to allow a minimum of 2.8” (70mm) insertion into the wall along with an additional 0.8” (20mm) to allow for the wall bracket and fixings. Three M12 threaded bars are required for each wall bracket.

6. The chemical resin can be placed into the gun and tested to ensure the two resins are mixing correctly. The two resins are individually colored white and light grey, but when dispensing the resin out of its nozzle, they should mix into a dark grey color. Ensure that this is the color of the resin.

7. Inject the holes with the chemical resin, the resin should fill 50% of the hole capacity.

8. Insert the three pieces of threaded bar into the holes. This will force the resin to fill the full hole capacity.

9. It is highly recommended that the threaded bars are twisted into the holes to provide additional strength and mix with the chemical resin.

10. Place the steel wall bracket onto the threaded bars.

11. Place an M12 washer and M12 nyloc nut onto the threaded bars and tighten onto the wall bracket for secure fixing.

12. Repeat these steps to secure all four steel wall brackets. The wall brackets must be fitted directly opposite to each other for level track fixing.

13. Allow each fixing time for the chemical resin to cure, see manufacturers curing times in the table in section 1.4.

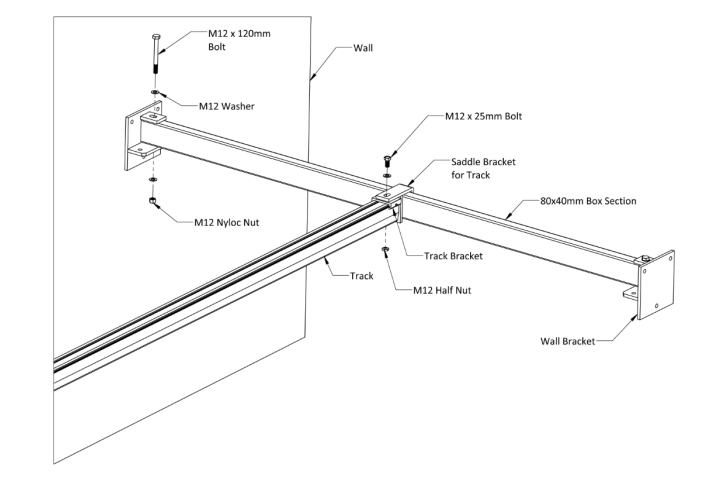

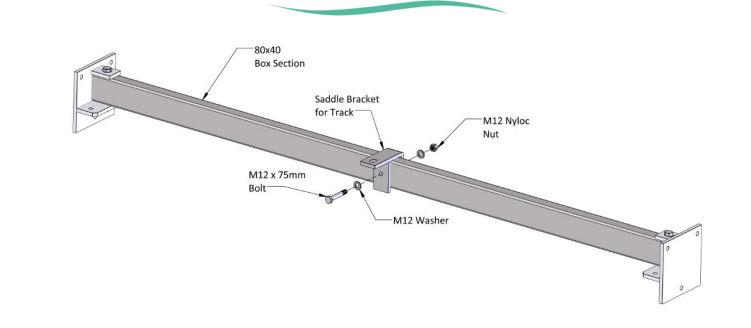

Wall-to-Wall Fixing Method 2 – Steelwork Assembly

The steel box section is spanned between the two walls and is fixed directly onto the steel wall brackets, this box section provides a fixing point for the saddle bracket and track.

The box section will require being cut to length to suit the spanning distance of the room. Follow the guidance below on how to attach the box section to the steel wall brackets correctly.

1. Position the steel box section into the steel wall brackets vertically. (as shown in the image).

2. From here, the hole positions on the steel box section can be determined and marked.

3. Drill a 13.5mm clearance hole to allow the fixings to pass through the box section at both ends.

4. From the center point of the box section, a 13.5mm clearance hole must be drilled into the side face for the saddle bracket fixing.

5. Reposition the box section onto the wall brackets and secure using an M12x120 bolt, ensure to place a washer at either end and secure using an M12 nyloc nut.

6. Repeat this process for both box sections onto all four wall brackets.

7. Position the saddle bracket centrally onto the box section and align it with the predrilled clearance hole.

8. Secure the saddle bracket onto the box section using an M12x75mm bolt, ensure to place a washer at either end, and secure using an M12 nyloc nut.

9. Attach a track bracket onto the saddle bracket using an M12x25mm bolt, ensure to place a washer between the bolt head and saddle bracket, and secure the track bracket using a single half nut. Apply Loctite 270 to the end of the bolt to secure the nut.